Honeycomb aluminum door manufacturing instructions: From A to Z

Share

Producing aluminum honeycomb doors is a process that requires meticulousness and high technique. To ensure the final product is of good quality, meeting aesthetic and technical requirements, you need to follow a strict production process.

1. Prepare materials:

- Honeycomb aluminum panels: Choose good quality honeycomb aluminum panels with thickness suitable for product requirements.

Alnavi honeycomb aluminum panels have superior thickness, good load-bearing capacity, and super sound insulation.

- Aluminum frame: Using high-quality aluminum profile, ensuring durability and aesthetics.

- Accessories: Hinges, locks, gaskets, handles,...

- Tools: Aluminum cutter, welding machine, drill, measuring tape, pencil,...

2. Production steps:

-

Drawing design:

- Determine the size and style of the door.

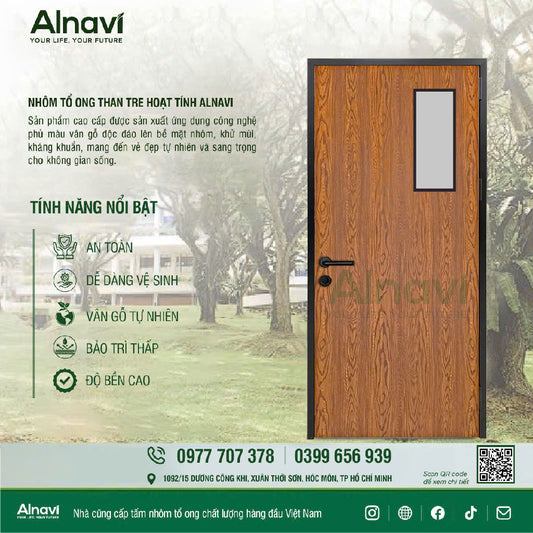

- Select glass type (if applicable).

- Draw the details of the door parts on the technical drawing.

-

Aluminum cutting:

- Use aluminum cutting machine to cut profile bars according to designed size.

- Ensure accurate, square cuts .

-

Processing:

- Drill holes for hinges, locks, and handles.

- Carve grooves for gasket installation.

-

Frame assembly:

- Connect the profile bars together with connecting corners and hinges.

- Check the squareness and firmness of the frame.

-

Installing honeycomb aluminum panels:

- Place the honeycomb aluminum panel inside the frame.

- Use specialized glue to firmly attach the honeycomb aluminum panels to the frame.

-

Glass installation (if any):

- Place the glasses in the designated position.

- Use gaskets and glue to secure the glass.

-

Install accessories:

- Install hinges, locks, and handles into the drilled locations.

- Adjust the door tightness.

-

Complete:

- Clean the product thoroughly.

- Check all doors before handover.

3. Some notes:

- Material quality: Choose good quality materials to ensure the durability and aesthetics of the product.

- Technique: Workers must be highly skilled and experienced to perform production stages.

- Tools: Use specialized machines and tools to ensure accuracy.

- Occupational safety: Comply with occupational safety regulations during production.

4. Advantages of Alnavi honeycomb aluminum doors:

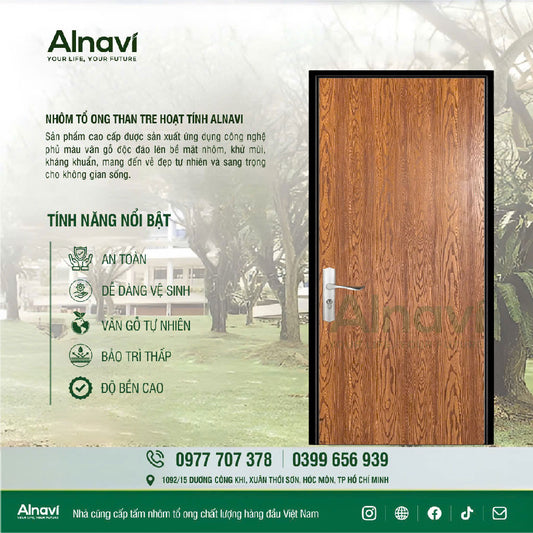

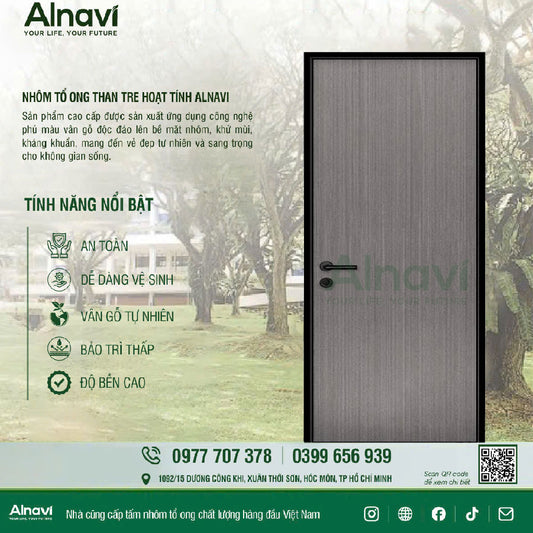

- Modern, luxurious beauty: Alnavi honeycomb aluminum doors with natural wood grain, combined with diverse colors, create a luxurious, modern beauty, suitable for many architectural styles.

- Effective sound and heat insulation: The honeycomb core inside the door helps block noise and heat from outside, providing a quiet and comfortable living space.

- High durability: Alnavi honeycomb aluminum has good load-bearing capacity, is resistant to warping and termites, ensuring durability over time.

- Fireproof: Safe for users and protects property.

- Environmentally friendly: Products are made from natural materials, do not contain toxic substances, safe for health.

- Easy to clean: Smooth surface, easy to clean.

- Diverse designs: Many styles and colors for you to choose from

Note: To produce high quality honeycomb aluminum doors, you should consult experts and use specialized design software.

Hopefully the above information will help you better understand the honeycomb aluminum door manufacturing process. If you need more detailed information, please contact:

1 comment

Bài viết ngắn gọn nhưng đầy đủ.